Build sponsored by:

Serpent

SerpentUK

Arrowmax-RC

RudeBits

Team-NCRC

AM-410116-BG Allen Wrench 1.5 X 100mm Black Golden

AM-410121-BG Allen Wrench 2.0 X 100mm Black Golden

AM-410126-BG Allen Wrench 2.5 X 100mm Black Golden

AM-410131-BG Allen Wrench 3.0 X 100mm Black Golden

AM-450145-BG Nut Driver 4.5 X 100mm Black Golden

AM-450150-BG Nut Driver 5.0 X 100mm Black Golden

AM-450155-BG Nut Driver 5.5 X 100mm Black Golden

AM-450170-BG Nut Driver 7.0 X 100mm Black Golden

AM-190008 TURNBUCKLE WRENCH 3MM – V2

AM-190025-P MULTI SHOCK-CLAMP V2

Optional:

AM-171063 Multi Alu Case For Screws (120X80X18MM) Black Golden

AM-171053 Tools Base Black Golden

AM-500902 Power Tool Tip Set 4 Pieces With Plastic Case (Metric)

Options I will use in this build:

#500139 Shocktower carbon fr SRX2

#500275 Shocktower carbon rr SRX2 MM

#500192 Geardiff set SRX2

#500644 Pro shock set rear SRX/SDX

#500645 Pro shock set front SRX/SDX

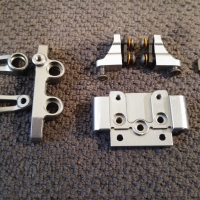

#500243 Front bulkhead alu SRX2

#500236 Steeringrack alu (3) SRX2

#500197 Servomount alu (2) SRX2

RudeBits R2 Wing

RudeBits Brass Shorty side weight

Setup and build manual used:

I will build the kit using the MHT (Medium to high traction) manual for high grip carpet, download the latest version of the Manual SRX2 – MHT Please remember that there are 2 sets of parts in the kit one for the LHT and the other for the MHT, make sure when you build you choose the correct bags.

LHT: Is for low to medium traction for example dirt tracks or grass, even possibly medium traction carpet.

MHT: Is for medium to high traction tracks such as carpet, astro turf and of course some clay tracks.

I will use Tony Evdoka’s Setup for the build, download the Maritime 3 GEAR Laydown November 2016

PetitRC Setup Sheet: Arno has made a nice easier editable setup sheet for the MH Download from his website

The Build features:

Tips from Tony Evdoka, Tony is one of the Serpent team developer drivers and has assisted in the development of this car so it is great to have insight from him for the build. I have known Tony for many years and he is also Serpent UK Offroad distributor. Also I have made a few comments as building.

Body painted and ready:

Thanks again to Tony for arranging the paintwork, paint done by Jim Currie and #Sickgrafix excellent detailing in the body, I love it.

Tony’s Tips:

Step 2: if you need more room for electrics then you can cut the 2 side skirts to gain extra room. It also allows the car to flex slightly more for added grip in that area. See pictures below for Tom’s cutting.

Step 4: You can add a 5mm thick washer (part number 110411) it then stays at 5mm gap with no need to measure again. http://serpent.com/product/110411

Step 5: You need a 5mm nut driver for the steering nuts

Step 7: 2 items here – The silver ring washer is critical for the servo horn. Must fit. Also must have the servo high enough so it doesn’t rub on the chassis. I have at least 1-2mm gap undermine. It allows the chassis to flex better for more steering and better over rough terrain Used ruler

Step 8: Many are not aware the front wing and the front anti-roll bare fit here instead of the little plug

Step 10: Once you have settled on the caster you like – I suggest you glue the caster insert to the steering hub – Remember that then you are sacrificing the hub to the insert.

I actually use the Short course Truck Steering blocks and C Hubs, the geometry is slightly different and makes the car easier to drive plus they are a little stronger than the kit ones.

part numbers 500316 http://serpent.com/product/500316 – 500317 http://serpent.com/product/500317

Step 12.1: I suggest the best tool on the market. Part number 190504 http://serpent.com/product/190504

Step 12.2: When more washers are desired on the inner ball stud, it’s important to change the ball for part number 500150 http://serpent.com/product/500150 as they are much longer and stay securely fitted. More washers, less initial steering, less washers more initial steering. Please do not mistake this for more or less steering. It’s the initial feel only

Step 12.2 continued: If you run 5 degrees caster fit a 2mm washer on hub side of turnbuckle Use the extra ball studs (5001509) from above modification, this stops spring from hitting the turnbuckle due to angle.

Also follow these tips: 5 degree caster 2mm washer, 2.5 degree caster 1mm washer 0 degree caster no washers, this means by looking at the washers you know exactly what caster you are running.

Step 15: I always use a light lock tight for any screw that fits into alloy.

Step 16: I personally never use oil on the UJs on the shafts. Oil in my opinion attracts dust and dirt and can be more damaging than the lack of lubrication from the first place Please also follow the same steps with the insert as in step 10 earlier

Step 17: Please note. Put left hub on the right and the right on the left

Step 18: I have recently found 2 plus 2 is a solid rear hinge pin set up

Step 19.2: Compress the spring before using

Step 22: I recommend small adjustments to make sure your diff doesn’t slip. I personally don’t like to tighten the diff then loosen it. Remember the slipper clutch must slip before the diff

Step 25: Do not over tighten the bolts clamping the gearboxes

Step 26: Compress slipper spring, with a large pair of pliers, a few times prior to fitting.

Step 27: Pinion to spur gear gap. Many fit paper and all sorts to make a gap – This is not enough. Make sure there it’s a tight gap but one you can actually hear when rocking the spur all the way round

Step 31: Shock stand offs are 7mm tool

Step 34: From the off I recommend the pro-shocks for long lasting racing success. Part numbers 500644 http://serpent.com/product/500644 – 500645 http://serpent.com/product/500645

Step 34.1: Make sure the hat washer as I call it is the right way round to fit the shock body

Step 34.2: Oil the ring before inserting into the adjusting ring for a much smoother turn up and down the shock adjusting thread

Step 35.1: Do not over tighten the M2 nut on a standard shock piston. Use lock tight

Step 35.2: Make sure you check set ups before adding the inner washers

Step 36.1: I personally don’t like the oil seals that come with the kit (if red) Remove completely or replace with 500179 http://serpent.com/product/500179

Tom: I Had issues before where these red seals got sucked through piston holes and locked up the shocks. Removing prevents and there are no leaks.

Step 38 and 39: – TOM: I always use the Arrowmax shock pliers to press the collars into the shocks

Step 39: The plastic nut on top of the shocks needs a 4.5 nut driver. It is critical it’s not over tightened. The shock caps must more freely on their mount

Step 48 TOM: Electrics layout I tried the default but did not like it so changed, see pictures below, first is default 2nd is my layout

- Default

- Changed

Exploded views in manual: Here you can check every part number here. Also in orange writing you can see if there are any upgrades available for that part too!

Enjoy your racing, Tony Evdoka Team Serpent

Build Video:

Build Gallery: