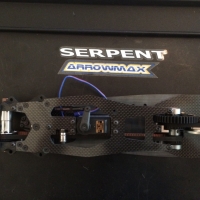

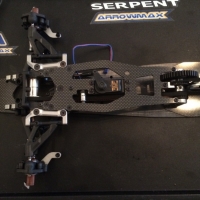

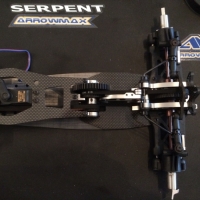

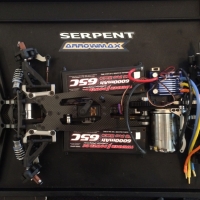

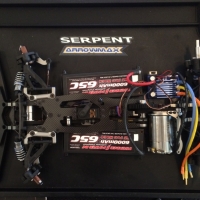

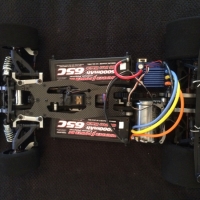

This is my first 1/8th onroad kit build and it was very easy to build, I encountered no problems with the build whatsoever.

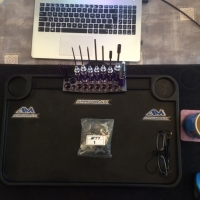

AM-110115 ALLEN WRENCH 1.5 X 120MM

AM-110120 ALLEN WRENCH 2.0 X 120MM

AM-110125 ALLEN WRENCH 2.5 X 120MM

AM-110130 ALLEN WRENCH 3.0 X 120MM

AM-110150 ALLEN WRENCH 5.0 X 120MM

AM-150155 NUT DRIVER 5.5 X 100MM

AM-190008 TURNBUCKLE WRENCH 3MM – V2

AM-190021 ARM REAMER 3.0 X 120MM

AM-190025-P MULTI SHOCK-CLAMP V2

AM-140140 PHILLIPS SCREWDRIVER 4.0 X 120MM

AM-130130 FLAT HEAD SCREWDRIVER 3.0 X 150MM

Optional:

AM-170044 SET-UP SYSTEM FOR 1/8 ON-ROAD CARS

AM-170063 Multi Alu Case for Screws (120X80X18)

AM-170030 SET-UP FRAME (M)

AM-170008 ALU SET-UP WHEEL FOR 1/8 ON-ROAD CARS (4)

AM-170052 TOOLS BASE

AM-500902 POWER TOOL TIP SET 4 PIECES WITH PLASTIC CASE

Non-Arrowmax Tools needed:

circlip pliers

knife

nail file from wife

Digital Calipers

needle nose pliers

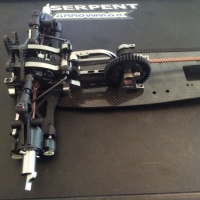

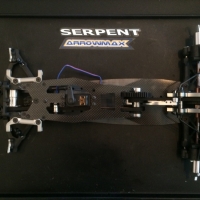

My overall impressions:

The kit was as per usual the kind of quality I have come to expect from Serpent, the build was a slow process but this was what was needed to build the car in the correct way.

My good friend and Serpent distributor Serdar Aytemiz here in Turkey had ordered a 977e kit to build for himself, so I asked if I could build it and use it here for Serpent and my website tomhow.com.

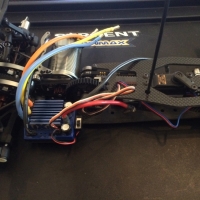

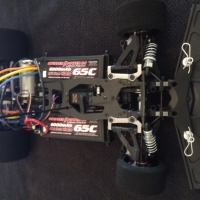

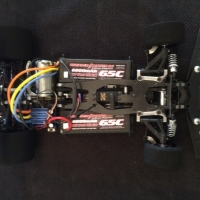

He agreed and gave me some parts to use for electrics. Remember to buy either battery tape or velcro straps to retain the battery as the kit does not have these included.

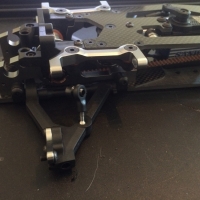

The build went very well and I had no issues, here are a few tips.

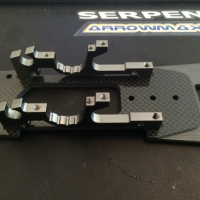

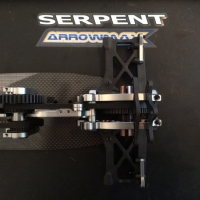

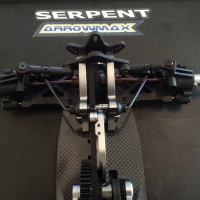

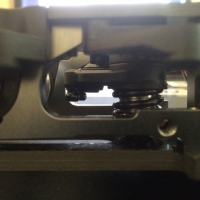

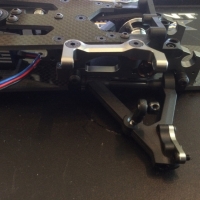

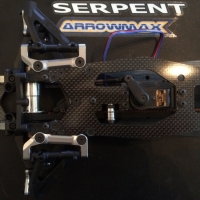

Step 13: You may want to sand down the castor shims a little if the arms when fitted with shims go tight, do this a little at a time until the arm is free when put together with shims. Repeat in Step 22.2 and Step 24

Step 14: You need a 5mm allen key for the bushes. Make sure when you set the pivot balls that you have free movement but no free play in them either, take your time, tighten up then back off a little at a time. Repeat in Step 25.3 and 25.4

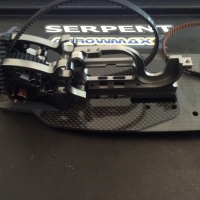

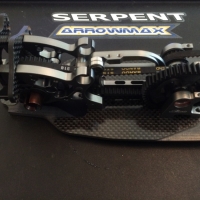

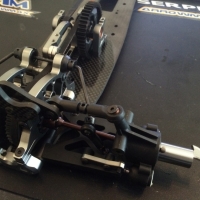

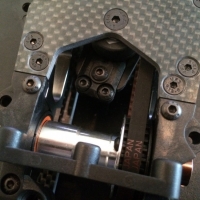

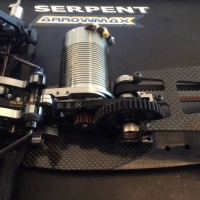

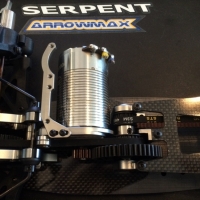

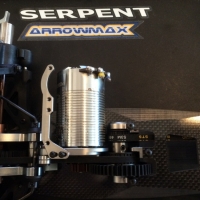

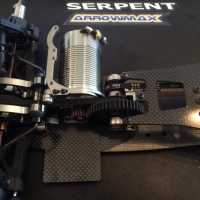

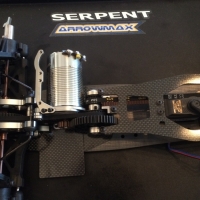

Step 35: When installing the motor plate I also attached the plate to the motor and then installed the plate as the inner screw by the spur gear was a bit tight to align motor screw without doing this step.

Video Gallery:

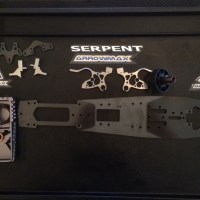

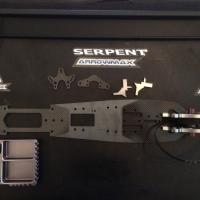

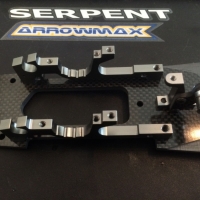

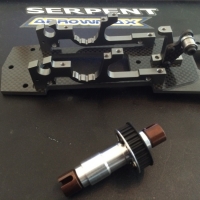

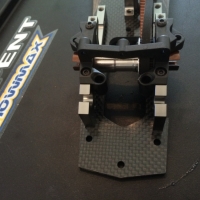

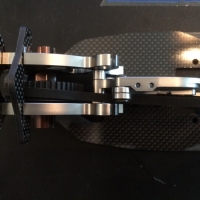

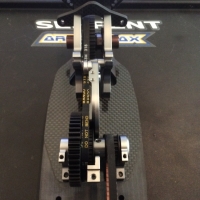

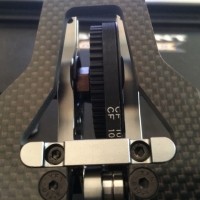

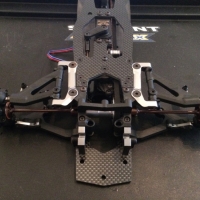

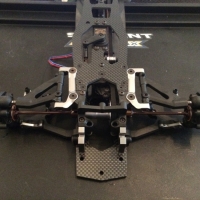

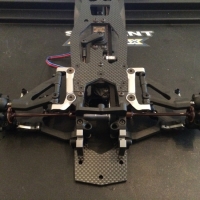

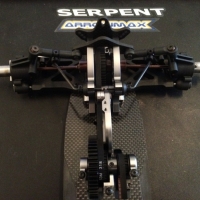

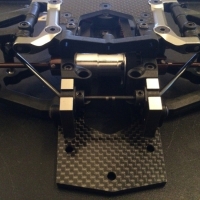

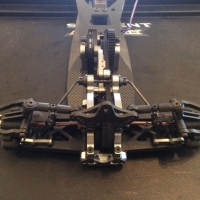

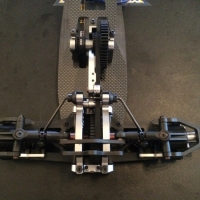

Image Gallery:

Use Left and Right Arrow Keys to go next or previous picture